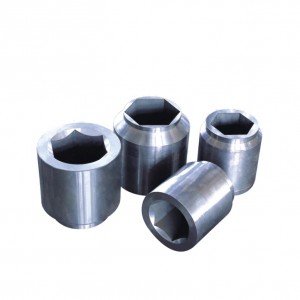

CNC Machined Part

Ningbo Jiangbei Xinye (NBXY),we specialize in providing high-precision CNC machining services for a wide range of projects. Our China precision CNC machining factory has been equipped with state-of-the-art modern advanced high precision machining facilities which including 3 axis CNC machining centers, 4 axis CNC machining centers, 5 axis CNC machining centers, CNC Milling

Using CNC machining, manufacturers can precisely shape a variety of materials, including metal, wood, plastic and composites, to create complex parts while ensuring consistency and perfection in the final product.

We offer CNC machining services for a variety of materials, Includes but not limited to:

Aluminium alloy: 6061, 6063, 6082, 7075

Brass alloy, Bronze alloy, Copper, Titanium alloy.

Stainless steel: 304, 316, 316L, 17-4, 17-4PH

Plastics: ABS, Delrin, Nylon, HDPE, Polypropylene,PET, PTFE, PVC, Teflon

Surface treatments include polishing, sand Blasting,colorless oxidation, plating, powder and more

General tolerance standard: DIN/ISO2768-f or better

we can achieve roughness levels ranging from Ra0.2 to Ra3.2 (customizable). Our tolerance level is with a minimum of ±0.01mm( also for customizable).

In the world of modern manufacturing, manufacturing innovative products relies heavily on cutting-edge technology and the pursuit of the highest precision. CNC machining is one of the technologies that is transforming entire industries. With its superior output and unparalleled quality, CNC machining has revolutionized manufacturing processes, allowing companies to reach new heights of efficiency and precision.

Unparalleled precision and accuracy:

The beauty of CNC machining is its exceptional precision, enabling tolerances as low as a few microns. Unlike traditional machining methods that rely heavily on human intervention, CNC machine tools follow a set of pre-programmed instructions with the highest precision. This eliminates the possibility of human error and ensures that every part produced is identical, resulting in a product of consistent quality.

Increase efficiency and speed up production:

By automating the process of CNC machining, manufacturers can significantly reduce production time. Once the initial setup is complete, the CNC machine can run continuously 24/7 without the need for constant supervision. With this unprecedented efficiency, companies can meet strict deadlines and scale production to meet growing demand, gaining a competitive advantage in an evolving market. Using CNC machining, manufacturers can precisely shape a variety of materials, including metal, wood, plastic and composites, to create complex parts while ensuring consistency and perfection in the final product

Quality and Consistency:

One of the most significant advantages of CNC machining is its ability to deliver unparalleled quality and consistency. The precision and accuracy these machines provide produces flawless parts that not only meet but exceed consumer expectations. Manufacturing consistency ensures that every product leaving the production line is of the same impeccable quality, further increasing customer satisfaction and brand reputation.

Cost-effective and versatile:

CNC machining offers cost savings that benefit businesses of all sizes. CNC machining minimizes production costs by eliminating manual labor and reducing material waste, thereby reducing overall manufacturing overhead. Additionally, CNC machines can handle a variety of materials and complex designs, allowing manufacturers to explore different applications without extensive retooling or reprogramming, maximizing efficiency and versatility.

In an era of technological advancement, As the demand for superior quality and cost-effective solutions continues to drive innovation, CNC machining remains at the forefront of the manufacturing revolution, shaping the future of industry like never before.