Key Takeaways

● The aviation fuel hydrant pit box helps refuel planes safely. It connects underground fuel systems to aircraft.

● Checking and maintaining the pit box every month is important. This keeps it working well and meets safety rules.

● Safety features like shut-off systems and spill control are included. These protect the environment and fueling process.

Components of an Aviation Fuel Hydrant Pit Box

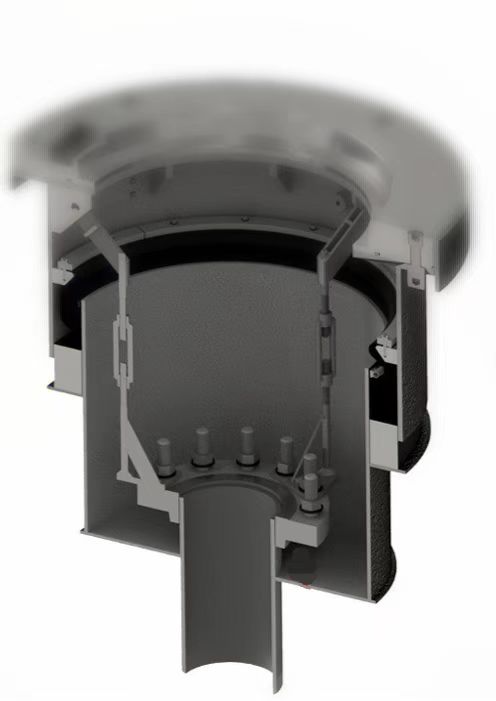

Pit Box Housing and Design

The housing of an aviation fuel hydrant pit box is built to withstand harsh conditions. You will notice that it is made from durable materials like stainless steel or aluminum. These materials resist corrosion and ensure long-term performance. The design focuses on functionality and safety. It provides easy access for fueling operations while protecting internal components from external damage. The compact structure also minimizes space usage on the tarmac, which is crucial in busy airports.

Hydrant Pit Valves and Couplers

Hydrant pit valves and couplers are the heart of the system. They control the flow of fuel from the underground pipeline to the aircraft. You can think of them as the connectors that ensure a secure and leak-free transfer. These components are designed to handle high pressure and prevent fuel spills. Quick-connect couplers make the process faster and safer, reducing the time an aircraft spends on the ground.

Monitoring Systems and Pressure Gauges

Monitoring systems and pressure gauges help you keep track of fuel flow and pressure levels. These tools ensure that the fueling process runs smoothly and safely. Pressure gauges provide real-time data, allowing you to adjust the flow as needed. Advanced monitoring systems can even detect irregularities, helping you address potential issues before they escalate.

Spill Containment and Drainage Features

Spill containment and drainage features are essential for environmental protection. The aviation fuel hydrant pit box includes built-in systems to capture and drain any spilled fuel. This prevents contamination of the surrounding area. You will find that these features are designed to comply with strict environmental regulations, ensuring that airports maintain eco-friendly operations.

How an Aviation Fuel Hydrant Pit Box Works

Integration with Underground Fuel Hydrant Systems

The aviation fuel hydrant pit box connects directly to underground fuel hydrant systems. These systems store and transport fuel through a network of pipelines beneath the airport. When you use the pit box, it acts as the access point for this fuel. The design ensures a seamless connection between the underground system and the aircraft. This eliminates the need for fuel trucks, reducing congestion on the tarmac. By integrating with underground systems, the pit box also minimizes the risk of fuel contamination and ensures a steady supply during refueling.

Fuel Delivery and Flow Control

Fuel delivery through the aviation fuel hydrant pit box is precise and efficient. The system uses hydrant pit valves to control the flow of fuel. When you connect the coupler to the aircraft, the valve opens to allow fuel transfer. Advanced flow control mechanisms ensure the fuel moves at the correct pressure and speed. This prevents overfilling and reduces the risk of spills. You can rely on the system to deliver the exact amount of fuel needed, saving time and improving operational efficiency.

Monitoring and Operational Efficiency

Monitoring systems in the aviation fuel hydrant pit box play a critical role in maintaining efficiency. Pressure gauges and sensors provide real-time data on fuel flow and pressure levels. You can use this information to make adjustments during refueling. Some systems even include automated alerts to notify you of irregularities, such as pressure drops or leaks. These features help you maintain smooth operations while ensuring safety. By combining monitoring tools with efficient design, the pit box supports faster turnaround times for aircraft.

Safety Features of an Aviation Fuel Hydrant Pit Box

Emergency Shut-Off Systems

Emergency shut-off systems are vital for ensuring safety during fueling operations. These systems allow you to stop fuel flow instantly in case of an emergency. For example, if a leak or pressure surge occurs, you can activate the shut-off mechanism to prevent further issues. Most aviation fuel hydrant pit boxes include manual and automatic shut-off options. The manual system lets you take control when needed, while the automatic system reacts to irregularities without delay. These features protect both the aircraft and the fueling crew, reducing the risk of accidents.

Fire-Resistant and Durable Materials

The materials used in an aviation fuel hydrant pit box are designed to withstand extreme conditions. Manufacturers use fire-resistant materials to minimize the risk of fire spreading during an incident. For instance, stainless steel and aluminum alloys are common choices because they resist heat and corrosion. These materials also ensure the pit box remains durable over time, even with constant exposure to fuel and weather. By using high-quality materials, the system maintains its integrity and keeps operations safe.

Spill Prevention and Environmental Protection

Spill prevention features in the aviation fuel hydrant pit box help you protect the environment. Built-in containment systems capture any fuel that might spill during refueling. Drainage systems then safely direct the captured fuel to designated storage areas. These features comply with environmental regulations, ensuring that airports operate responsibly. By preventing spills, you also reduce the risk of soil and water contamination. This makes the pit box an eco-friendly solution for modern aviation fueling needs.

Maintenance and Inspection of an Aviation Fuel Hydrant Pit Box

Routine Maintenance Practices

Routine maintenance ensures the smooth operation of your aviation fuel hydrant pit box. You should regularly clean the pit box to remove debris and dirt that may accumulate over time. This prevents blockages and ensures proper drainage. Lubricating moving parts, such as hydrant pit valves and couplers, helps reduce wear and tear. You should also check for signs of corrosion or damage on the housing and replace any worn-out components promptly. By following these practices, you can extend the lifespan of the system and maintain its efficiency.

Inspection Standards and Frequency

Regular inspections are essential for identifying potential issues before they become serious. You should inspect the aviation fuel hydrant pit box at least once a month. During inspections, check the pressure gauges and monitoring systems to ensure they are functioning correctly. Look for leaks, cracks, or other signs of damage. Annual inspections by certified professionals are also recommended. These inspections often include pressure testing and a thorough review of all components. Following these standards helps you maintain safety and compliance with industry regulations.

Addressing Common Issues and Repairs

Even with proper maintenance, issues can arise. Common problems include leaks, pressure irregularities, and damaged couplers. If you notice a leak, you should address it immediately to prevent environmental contamination. Replacing faulty valves or couplers can resolve most pressure-related issues. For more complex repairs, consult a professional technician. Keeping spare parts on hand can help you resolve minor problems quickly. By addressing issues promptly, you can avoid costly downtime and ensure the reliability of your aviation fuel hydrant pit box.

The aviation fuel hydrant pit box is essential for modern aviation fueling systems. It ensures safe and efficient refueling while protecting the environment. By using this system, you enhance operational safety, reduce downtime, and meet environmental standards. Its innovative design and features make it a cornerstone of sustainable airport operations.

FAQ

What is the purpose of an aviation fuel hydrant pit box?

The pit box ensures safe and efficient fuel transfer from underground systems to aircraft. It minimizes environmental risks and supports smooth airport operations.

Tip: Regular maintenance keeps the pit box functioning optimally.

How often should you inspect an aviation fuel hydrant pit box?

You should inspect it monthly for leaks, damage, or irregularities. Annual professional inspections ensure compliance with safety and industry standards.

Can the pit box handle extreme weather conditions?

Yes, manufacturers design it with durable, fire-resistant materials like stainless steel. These materials withstand harsh weather and ensure long-term reliability.

Note: Always check for corrosion or wear during routine maintenance.

Post time: Apr-07-2025