the parts of gas detector/flame detector

Gas and flame detectors protect you from hazardous conditions by identifying risks early. Each part of these devices plays a critical role in their operation. Understanding these components helps you maintain them effectively. It also ensures workplace safety. An accessories manufacturer can provide essential parts to keep your detectors reliable.

Key Takeaways

- Gas and flame detectors help find dangers early to save lives and property.

- Checking and adjusting sensors often keeps them working correctly and reliably.

- Good-quality parts from trusted brands make detectors last longer and work better.

Overview of Gas and Flame Detectors

What Are Gas Detectors?

Gas detectors are devices that identify harmful gases in the air. These tools help you detect toxic or combustible gases before they reach dangerous levels. They are commonly used in industries like manufacturing, mining, and oil and gas. Gas detectors rely on sensors to measure gas concentrations. When the levels exceed safe limits, the device triggers an alarm to warn you.

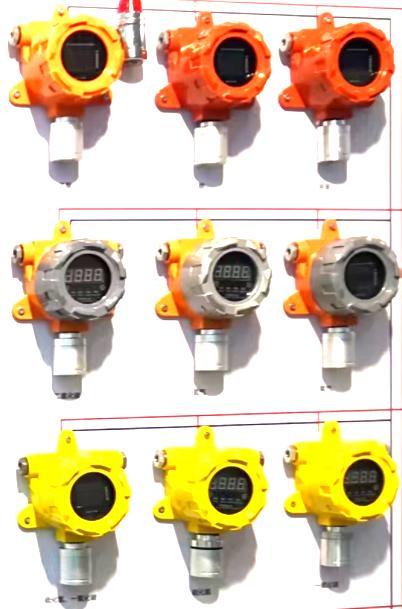

You can find gas detectors in two main types: portable and fixed. Portable detectors are lightweight and easy to carry. Fixed detectors are installed in specific locations to monitor continuously. Both types play a vital role in keeping you safe from gas-related hazards.

What Are Flame Detectors?

Flame detectors are safety devices that identify the presence of fire. They use advanced sensors to detect ultraviolet (UV) or infrared (IR) radiation emitted by flames. These detectors respond faster than traditional smoke detectors. This quick response helps you act immediately to prevent fire damage.

Flame detectors are often used in high-risk areas like chemical plants, refineries, and storage facilities. They can detect flames even in challenging conditions, such as smoky or dusty environments. Their reliability makes them essential for fire safety systems.

Importance in Safety Systems

Gas and flame detectors are critical for protecting lives and property. They provide early warnings, allowing you to take action before a situation becomes dangerous. Without these devices, hazardous conditions could go unnoticed.

Tip: Regular maintenance ensures your detectors work effectively when you need them most.

By understanding how these detectors function, you can create a safer environment for everyone.

Key Components of Gas Detectors

Sensors

Sensors are the heart of any gas detector. They identify and measure the concentration of gases in the air. Different types of sensors exist, such as electrochemical, catalytic bead, infrared, and photoionization detectors (PID). Each type specializes in detecting specific gases. For example, electrochemical sensors are ideal for toxic gases like carbon monoxide, while catalytic bead sensors detect combustible gases.

Note: Regular calibration ensures sensors provide accurate readings.

Sensors continuously monitor the environment. When they detect gas levels exceeding safe thresholds, they send signals to the control unit.

Alarms and Indicators

Alarms and indicators alert you when gas levels become dangerous. These components include visual signals like flashing lights and audible alarms like sirens. Some detectors also feature digital displays showing real-time gas concentrations.

Tip: Choose detectors with loud alarms and bright indicators for better visibility and audibility in noisy environments.

These alerts ensure you can respond quickly to potential hazards.

Power Supply

The power supply keeps your gas detector operational. Most detectors use batteries, while fixed systems may rely on direct electrical connections. Rechargeable batteries are common in portable detectors.

Reminder: Check battery levels regularly to avoid unexpected power loss.

A reliable power source ensures uninterrupted monitoring.

Control Unit

The control unit processes data from the sensors. It determines whether gas levels are within safe limits. If the levels exceed the threshold, the control unit activates alarms and other safety measures. Advanced control units may also store data for analysis.

This component acts as the brain of the gas detector, ensuring all parts work together seamlessly.

Housing and Enclosure

The housing protects the internal components from damage. It shields the detector from environmental factors like dust, moisture, and extreme temperatures. Durable materials like stainless steel or high-grade plastic are often used.

Tip: Ensure the housing is suitable for your work environment to maximize durability.

Proper housing extends the lifespan of your gas detector and ensures reliable performance.

Key Components of Flame Detectors

UV Sensors

UV sensors detect ultraviolet radiation emitted by flames. These sensors respond quickly to the presence of fire, often within milliseconds. They are highly effective in environments where flames produce minimal smoke. For example, they work well in clean-burning fuel applications.

Tip: Use UV sensors in areas with minimal UV interference, such as indoor spaces, to avoid false alarms caused by sunlight or welding arcs.

UV sensors are reliable but may not perform well in outdoor settings with high UV exposure.

IR Sensors

IR sensors identify infrared radiation from flames. They excel in detecting fires in environments with heavy smoke or dust. These sensors are less prone to false alarms caused by sunlight, making them suitable for outdoor use.

IR sensors monitor specific wavelengths of infrared light. When they detect the unique pattern of a flame, they trigger an alert. This capability makes them ideal for industrial settings like oil refineries or chemical plants.

Combined UV/IR Sensors

Combined UV/IR sensors offer the best of both technologies. They detect both ultraviolet and infrared radiation, reducing the chances of false alarms. These sensors are highly versatile and can operate in challenging conditions, including outdoor environments.

Note: Combined sensors are more expensive but provide enhanced reliability and accuracy.

You can use these sensors in high-risk areas where safety is a top priority.

Signal Processor

The signal processor analyzes data from the sensors. It determines whether the detected radiation matches the characteristics of a flame. This component filters out false signals caused by non-flame sources, such as sunlight or hot surfaces.

Advanced signal processors improve detection accuracy. They ensure the system only triggers alarms when a real fire is present.

Housing and Mounting

The housing protects the flame detector from environmental damage. It shields the internal components from dust, moisture, and extreme temperatures. Durable materials like stainless steel or aluminum are commonly used.

Proper mounting ensures the detector covers the desired area effectively. Adjustable mounts allow you to position the detector for optimal performance.

Reminder: Regularly inspect the housing and mounting to ensure the detector remains secure and functional.

A well-maintained housing extends the lifespan of your flame detector and ensures reliable operation.

Role of Accessories Manufacturer in Detector Systems

Importance of Spare Parts and Accessories

Spare parts and accessories are essential for keeping your gas and flame detectors operational. Over time, components like sensors, batteries, and alarms wear out or fail. Replacing these parts promptly ensures your detectors continue to function effectively. Accessories like calibration kits and mounting brackets also play a crucial role in maintaining accuracy and stability.

An accessories manufacturer provides these critical items, helping you avoid downtime. Without access to quality spare parts, your safety systems could become unreliable. Regularly checking and replacing worn-out components ensures your detectors remain ready to respond to hazards.

Examples of Essential Accessories

You can find a variety of accessories designed to enhance the performance of your detectors. Some common examples include:

- Calibration Kits: These help you test and adjust sensors for accurate readings.

- Replacement Sensors: Essential for restoring functionality when original sensors degrade.

- Mounting Brackets: Ensure proper positioning for optimal detection.

- Protective Covers: Shield detectors from environmental damage like dust or moisture.

An accessories manufacturer offers these items to meet your specific needs. Choosing the right accessories improves the reliability and lifespan of your detectors.

Ensuring System Reliability Through Quality Accessories

Using high-quality accessories is vital for maintaining system reliability. Poor-quality parts can lead to false alarms or missed detections, putting you at risk. A trusted accessories manufacturer ensures their products meet industry standards. This guarantees compatibility and durability.

Tip: Always source accessories from reputable manufacturers to avoid compromising your safety systems.

Investing in quality accessories reduces the likelihood of system failures. It also ensures your detectors perform as expected in critical situations.

How These Components Work Together

Integration of Sensors and Alarms

Sensors and alarms work together to ensure your safety. Sensors continuously monitor the environment for gas or flame hazards. When they detect a dangerous level of gas or the presence of a flame, they send signals to the alarm system. The alarms then activate, providing you with immediate visual and audible warnings. This integration allows you to respond quickly to potential threats.

For example, in a gas detector, the sensor measures gas concentration. If the levels exceed the safe threshold, the alarm alerts you to evacuate or take corrective action. Similarly, in a flame detector, the sensor identifies radiation patterns from a fire and triggers the alarm. This seamless connection between sensors and alarms ensures you are always informed of hazards.

Role of the Control Unit in System Functionality

The control unit acts as the brain of the detection system. It processes data from the sensors and determines whether the detected levels pose a risk. If a hazard is confirmed, the control unit activates the alarms and may initiate additional safety measures, such as shutting down equipment.

Advanced control units can also store data for analysis. This feature helps you identify patterns and improve safety protocols. A reliable control unit ensures all components work together efficiently, enhancing the overall effectiveness of your detection system.

Ensuring Reliability Through Proper Housing

The housing protects the internal components of your detectors from environmental damage. It shields sensors, alarms, and the control unit from dust, moisture, and extreme temperatures. Durable housing materials, such as stainless steel or high-grade plastic, ensure your detectors remain functional in harsh conditions.

Proper housing also prevents accidental damage during installation or maintenance. Accessories manufacturers often provide protective covers and mounting brackets to enhance durability. By choosing high-quality housing and accessories, you can extend the lifespan of your detectors and maintain their reliability.

Gas and flame detectors protect you from hazardous conditions. Each part, from sensors to accessories, ensures the system works effectively. Understanding these components helps you maintain safety and reliability.

Reminder: Regular maintenance and quality accessories keep your detectors operational. Your knowledge of these systems can prevent accidents and save lives.

FAQ

What is the lifespan of a gas detector sensor?

Most gas detector sensors last 2-5 years. Regular calibration and maintenance extend their lifespan. Always check the manufacturer’s guidelines for specific recommendations.

Tip: Replace sensors promptly to maintain accurate readings.

Can flame detectors work in outdoor environments?

Yes, flame detectors with IR or combined UV/IR sensors perform well outdoors. They resist false alarms caused by sunlight or environmental factors like dust.

Reminder: Choose detectors designed for outdoor use for better reliability.

How often should you calibrate gas detectors?

Calibrate gas detectors every 6-12 months. Frequent calibration ensures accurate readings and reliable performance. Follow the manufacturer’s instructions for the best results.

Note: Use calibration kits for precise adjustments.

Post time: Jan-31-2025